Ci gaba da Extrusion Machinery

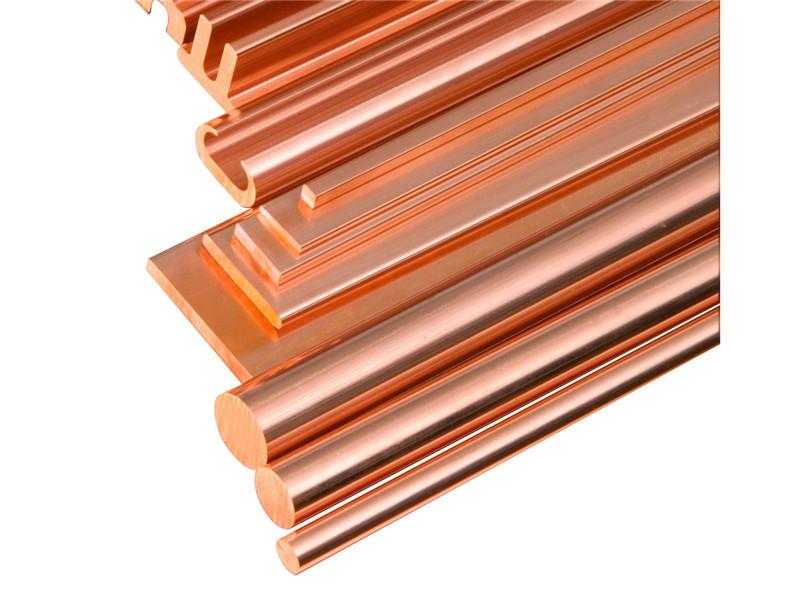

Amfani

1, nakasar filastik na sandar ciyarwa a ƙarƙashin ƙarfin juzu'i da zafin jiki mai girma wanda ke kawar da lahani na ciki a cikin sandar da kanta gaba ɗaya don tabbatar da samfuran ƙarshe tare da kyakkyawan aikin samfur da daidaito mai girma.

2, ba preheating ko annealing, mai kyau ingancin kayayyakin samu ta extrusion tsari tare da ƙananan ikon amfani.

3, tare da ciyar da sandar girman girman guda ɗaya, injin zai iya samar da nau'ikan samfura da yawa ta amfani da mutuwa daban-daban.

4, duk layin yana aiki cikin sauƙi da sauri ba tare da wani aiki mai nauyi ko gurɓatacce ba yayin extrusion.

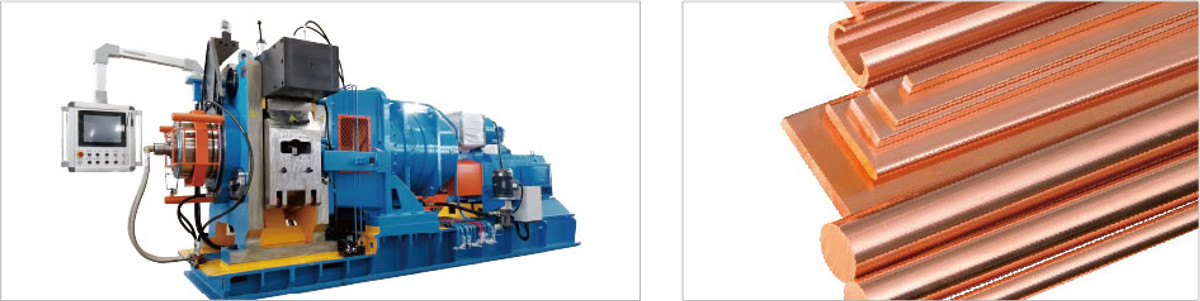

Ciyarwar sandar jan karfe

1.Don yin wayoyi masu lebur na jan ƙarfe, ƙaramin bus ɗin jan ƙarfe da waya zagaye

| Samfura | Farashin TLJ300 | TLJ 300H |

| Babban Mota (kw) | 90 | 110 |

| Ciyarwar sanda dia.(mm) | 12.5 | 12.5 |

| Max.Nisa samfurin (mm) | 40 | 30 |

| Flat Waya Cross-Sectional | 5-200 | 5-150 |

| Fitowa (kg/h) | 480 | 800 |

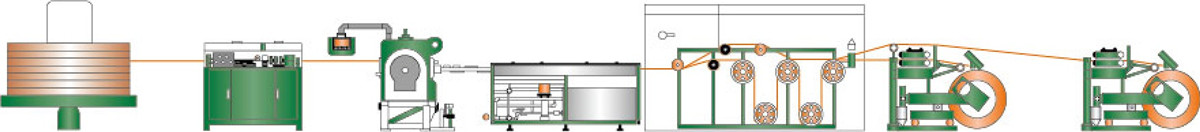

Tsarin Layin Samfura

Biya-kashe Pretreatment Extrusion Machine Cooling Sys.Injin ɗaukar rawa na rawa

2.Don yin jan busbar, jan karfe zagaye da jan profile

| Samfura | Farashin TLJ350 | Farashin TLJ350H | Farashin TLJ400 | Farashin TLJ400H | Farashin TLJ500 | Farashin TLJ630 |

| babban wutar lantarki (kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| sandar ciyarwa dia.(mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max.Nisa samfurin (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| samfurin sanda dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| Wurin giciye samfurin (mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| fitarwa (kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

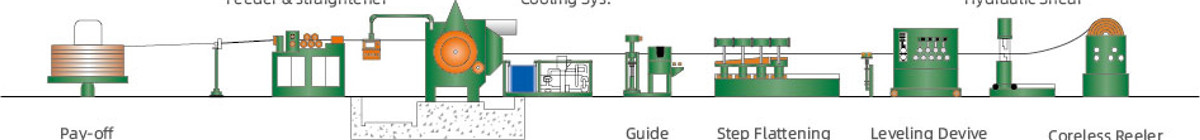

Tsarin Layin Samfura

Feeder & Madaidaici Extrusion Machine Cooling Sys.Injin ɗaukar Bench ɗin Tsawon Tsawon samfur

3. Don yin tagulla basbar, jan karfe

| Samfura | TLJ 500U | Farashin TLJ600U |

| babban wutar lantarki (kw) | 355 | 600 |

| sandar ciyarwa dia.(mm) | 20 | 30 |

| max.Nisa samfurin (mm) | 250 | 420 |

| max.nisa zuwa kauri rabo | 76 | 35 |

| kauri samfurin (mm) | 3-5 | 14-18 |

| fitarwa (kg/h) | 1000 | 3500 |

Tsarin Layin Samfura

Copper gami sanda ciyar

Neman madugu na commutator, brass blank, phosphor jan sanda, firam firam ɗin gubar, layin layin dogo da dai sauransu.

| Farashin TLJ350 | Farashin TLJ400 | Farashin TLJ500 | Farashin TLJ630 | |

| abu | 1459/62/63/65 tagulla cu/Ag (AgsO.08%) | phosphor jan ƙarfe (Pso.5%) cu/Ag (AgsO.3%) | magnesium jan karfe (MgsO.5%) ƙarfe jan ƙarfe (Feso.l% | magnesium jan karfe (MgsO.7%) / Cucrzr |

| sandar ciyarwa dia.(mm) | 12/12.5 | 20 | 20 | 25 |

| max.Nisa samfurin (mm) | 30 | 150 (tsarin jan karfe na azurfa) | 100 (gubar firam:) | 320 |

| samfurin sanda dia.(mm) | phosphor tagulla: 10-40 | magnesium tagulla: 20-40 | magnesium tagulla: 20-40 | |

| fitarwa (kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

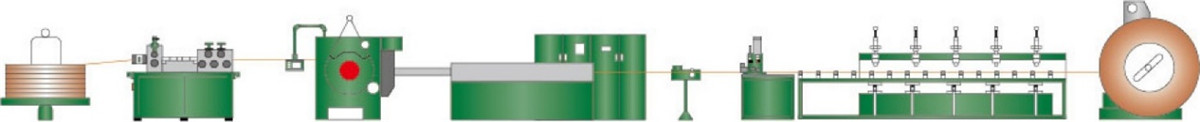

Tsarin Layin Samfura

Feeder & Madaidaici Extrusion Machine Cooling Sys.Na'ura mai ɗaukar tsayin tsayi

Aluminum sanda ciyar

Neman waya mai lebur, mashaya bas, da jagorar bayanin martaba, bututu mai zagaye, MPE, da bututun PFC

| Samfura | LLJ 300 | LLJ 300H | LLJ 350 | LLJ 400 |

| babban wutar lantarki (kw) | 110 | 110 | 160 | 250 |

| sandar ciyarwa dia.(mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max.Nisa samfurin waya mai lebur (mm) | 30 | 30 | 170 | |

| Flat waya samfurin yanki giciye (mm2) | 5-200 | 5-200 | 25-300 | 75-2000 |

| zagaye tube dia.(mm) | 5-20 | 5-20 | 7-50 | |

| Faɗin tube (mm) | - | ≤40 | ≤70 | |

| lebur waya / bututu fitarwa (kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

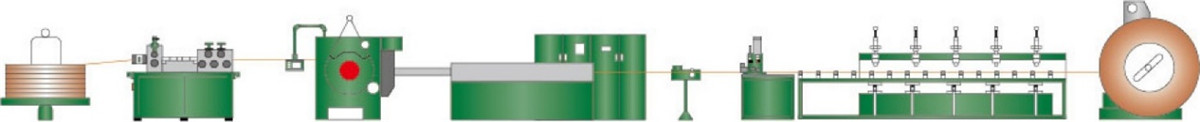

Tsarin Layin Samfura

Pay-off straightener Ultrasonic tsaftacewa Cooling Sys Dancer Take-up Machine

Hoton 217282